Based on the good experience with the Shock Pulse Generators for boiler cleaning in the presently decommissioned waste incineration plant Real in Lucerne/CH, the operator of the new built plant Renergia in Perlen has again installed the SPGs of Explosion Power GmbH for cleaning of the first three boiler passes. Such operate to the full satisfaction of the customer since 2015.

The aging KVA Luzern (Real) needed to be replaced. As a replacement, and to increase the disposal capacity, a new plant was built at the Perlen paper mill site (Renergia), close to Luzern. This new plant was built using the most recent developments in waste incineration technology. It was commissioned in January 2015.

The operator of the former plant was very innovative and had tested several processes, some of which were used in the design of the new plant. Excellent experience with boiler cleaning using SPGs from Explosion Power GmbH was also gained. The three boilers of the previous plant were solely cleaned using SPGs. At the operator’s request, the positive experience was also applied to the new plant.

The new plant consists of two parallel process lines. The steam produced is used to generate electricity and to supply the Perlen paper mill with process steam, as well as several households with district heating. In addition, an extension of the district heating system for surrounding communities is under construction, resulting in an optimal synergy of waste recycling. An innovative flue gas and residues treatment leads to a progressive emission reduction while providing excellent energy efficiency.

System of the boiler cleaning

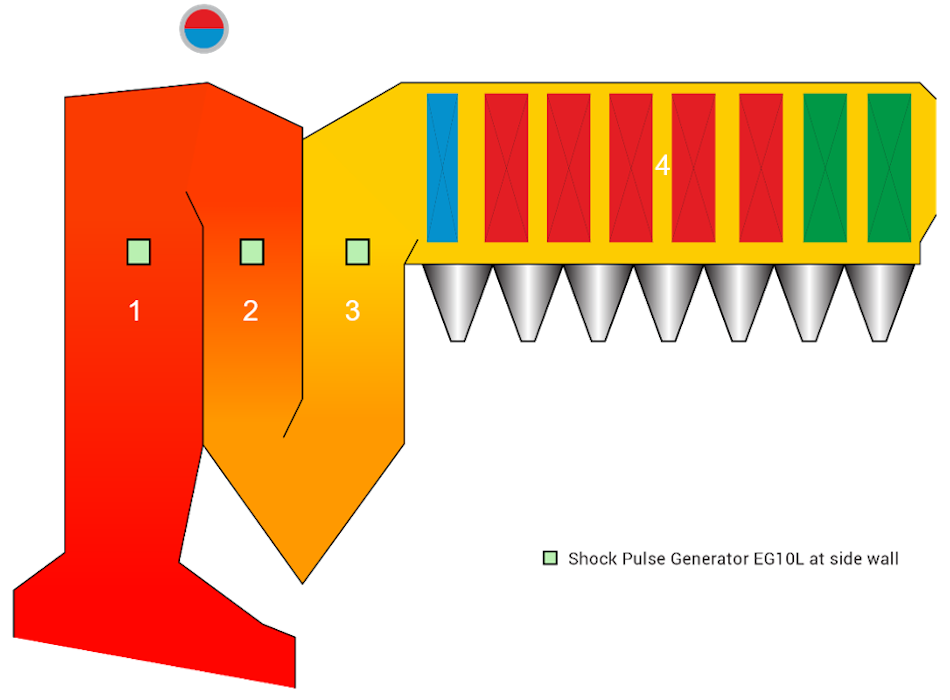

The 4-pass boiler takes over the hot flue gases from the combustion grate and is responsible for optimum utilization of the generated heat. However, ash particles also escape in this stream, which then adhere to the boiler walls and the tube heat exchangers.

Explosion Power GmbH has provided uniform SPG (type EG10L), for each of the first, second and third boiler passes. These SPGs are installed from the boiler side. Thus, the radiation passes of both lines are equipped with a total of six identical SPGs. The horizontal fourth boiler pass, the convective part, is cleaned by pneumatic hammers.

Graphic of Explosion Power GmbH

How often are the SPGs operated?

The walls of the first boiler pass are protected by Inconel build-up welding. This is where the highest temperatures and the largest ash accumulations are recorded. The danger of the formation of ash caking must be taken into consideration. The SPG type EG10L keeps the walls free of unwanted build-up.

The shock pulse intervals of the three radiation passes are varied so that a constant flue gas temperature can be achieved. On average these are 8 hours per SPG for the first pass, 3 hours per SPG for the second pass and 2-3 hours per SPG for the third pass.

Do the SPGs meet the operator’s expectations?

The operator is absolutely satisfied with the cleaning performance, the functionality and the low maintenance of the SPGs. The following statements by Mr. Markus Benz, head of mechanical maintenance of the plant, also prove this:

«Thanks to the shock pulse generators, there’s minimal buildup in the 1st, 2nd and 3rd boiler pass. Thus, the flue gas temperatures upstream of the protective evaporator are significantly lower. Among other things, such become an important factor for increasing the interval of our operational maintenance times from 12 to 18 months. »

Since the commissioning in January 2015, the first three passes have never been completely sandblasted during the planned maintenance work. Sandblasting was only carried out locally where wall thickness measurements were necessary.

In addition to the annual revision of the service contract with Explosion Power GmbH, about two hours per half-year are spent on small inspections for each SPG. This work is carried out by the operator.

The gas consumption per pulse trigger corresponds to the manufacturer’s specifications. For industrial operation, only the total consumption of all installed SPGs is measured, because this is of interest when calculating operating costs.

Gas storage and distribution

The new plant has been designed for the use of SPGs. Two separate compartments were constructed from reinforced concrete for storing the necessary gases. One compartment houses the oxygen battery and a nitrogen cylinder with the corresponding pressure reducing valves. The gases are supplied by a gas supplier in a pendulum cycle.

The paper mill has a permanent connection to natural gas at approximately 30 bar. A compressor fills each natural gas battery at a pressure of 200 bar. The filled battery is transported to the natural gas compartment for replacement.

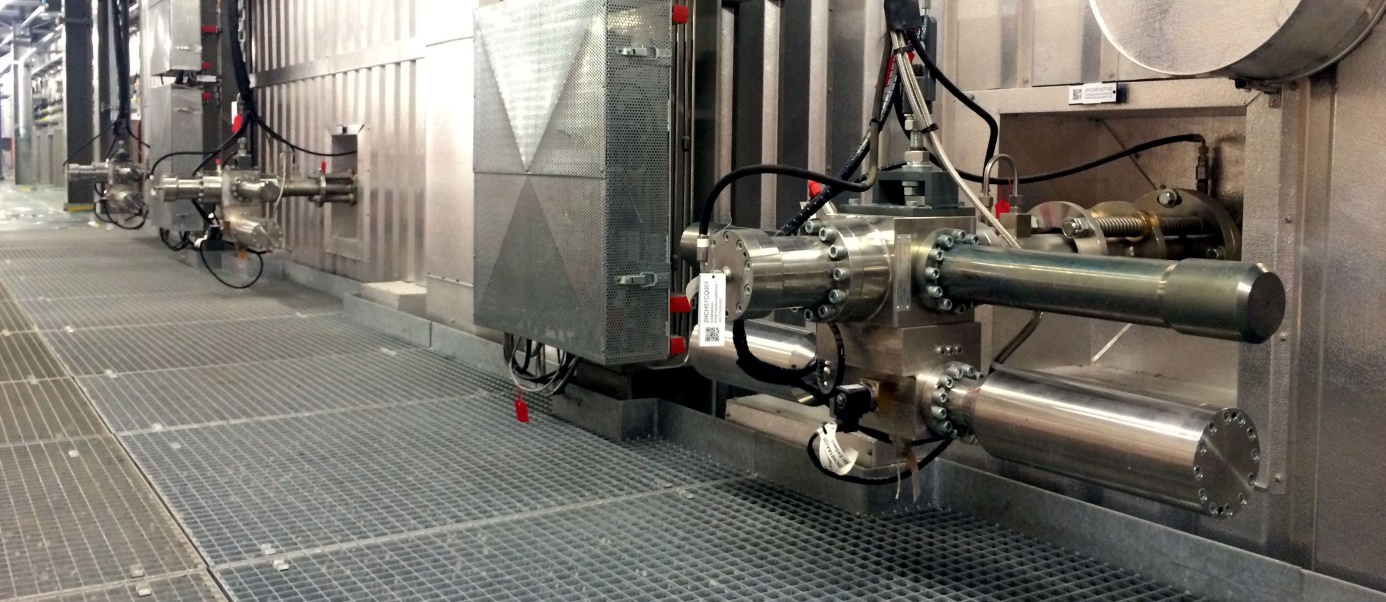

All supply lines up to the valve panels of the SPGs at the boiler are made of stainless steel pipes.

Photo by Explosion Power GmbH

Assembly and commissioning

The assembly was carried out by Explosion Power GmbH. The SPGs were flanged onto the prepared DN125 boiler nozzles.

A problem-free commissioning and training was also carried out by the supplier. The maintenance personnel of Renergia completed extensive training at Explosion Power GmbH, which allows them to perform much of the maintenance themselves.

Control of the generators

Each SPG is assigned a valve panel. The SPGs are controlled individually from a common control cabinet. Each boiler line has one control cabinet.

Fig 5: Each SPG has a valve panel (left) and a control cabinet EG104 (right), with three SPGs per boiler line. Photo by Explosion Power GmbH

The entire waste incineration plant is controlled from the central control system.

The boiler cleaning sequence is also triggered from there.

Main data of Renergia:

Operator: Renergia Zentralschweiz AG

Commercial operation from: February 2015

Annual capacity: 200.000 metric tons of municipal and commercial waste

Number of lines: 2

Waste throughput (nominal): 12,5 t/h per line

Thermal power: 47 MW per line

Steam output: 58 t/h per line

Steam parameters: 410°C / 41 bar

Steam utilization: Extraction condensing turbine max. 67,8 MWe,

with process steam and district heating

Flue gas treatment: multi-stage technology, effluent-free